Cenospheres (UltraLightSphere):

Your Solution for Lightweight Versatility

Cenospheres are unique, lightweight, hollow spheres derived from the ash produced during coal combustion in power plants. These microspheres possess an impressive combination of properties, making them incredibly versatile for various applications.

Orient has pioneered the development of Cenospheres, presenting them under our distinguished brand, Ultralightspheres. We have invested significant efforts and resources in refining the quality and consistency of these Cenospheres to ensure they meet the highest industry standards.

The Advantages of Cenospheres:

- Lightweight Nature and Low-Density Filler: Cenospheres are exceptionally lightweight due to their hollow, spherical structure. This property is particularly valuable in industries where weight reduction is paramount. As a low-density filler, Cenospheres seamlessly blend into various materials without compromising the overall density, improving strength and reducing weight.

- Impressive Strength: Despite their lightweight character, Cenospheres possess remarkable compressive strength, making them an ideal choice for various composite materials, enhancing structural integrity.

- Outstanding Thermal Insulation: Cenospheres offer excellent thermal insulating properties, making them essential in applications that require efficient temperature control, such as the construction and oil and gas industries.

- Chemical Inertness: Cenospheres are chemically inert, ensuring they do not corrode or degrade in different environments. This quality makes them a durable choice for numerous applications.

- Improved Abrasion Resistance: Incorporating Cenospheres into paints and coatings significantly enhances their abrasion resistance, making them more durable and resilient against wear and tear.

- Acoustic Insulation: Cenospheres have acoustic insulating properties, making them suitable for applications where sound absorption and noise reduction are required.

Applications Across Industries:

Unleashing Strength, Reducing Weight, and Enhancing Comfort

Cenospheres are construction’s hidden gem. When added to concrete, plaster, and building materials, they work their magic:

- Weight Reduction: Cenospheres lighten the load of construction materials, facilitating easier handling and reducing transportation costs.

- Strength Enhancement: Surprisingly, Cenospheres, with their lightweight nature, increase the compressive strength of materials, ensuring structures are rock-solid.

- Thermal Insulation: As an insulator, they boost the energy efficiency of buildings, providing comfort in every season.

- Sound Absorption: Cenospheres also contribute to quieter living and working spaces, improving acoustic comfort.

Redefining Drilling and Cementing with Efficiency and Resilience.

In the challenging world of oil and gas exploration, Cenospheres prove to be invaluable:

- Weight Reduction: Lighten drilling fluids and cementing materials, optimizing pressure control during drilling operations.

- Thermal Insulation: Cenospheres keep the temperature under control, performing exceptionally well in extreme environments.

- Chemical Inertness: Resistant to corrosion, they are the perfect choice for withstanding corrosive oil well environments.

Elevating Flight Performance and Safety with Lightness and Strength.

Cenospheres find their way into the aerospace industry, enhancing flight in more ways than one:

- Weight Savings: By reducing the weight of aircraft and spacecraft components, Cenospheres increase fuel efficiency and payload capacity.

- Structural Integrity: They play a crucial role in ensuring structural integrity, making every flight safer.

- Thermal Insulation: As a thermal insulator, Cenospheres protect vital equipment from extreme temperatures during space travel.

- Acoustic Comfort: The noise reduction properties of Cenospheres make flights more enjoyable and peaceful.

Driving Efficiency, Reducing Emissions, and Boosting Durability.

In the automotive industry, Cenospheres are on a mission to revamp vehicles:

- Weight Reduction: By incorporating Cenospheres into lightweight components, vehicles become more fuel-efficient and eco-friendlier.

- Fuel Efficiency: Lighter vehicles consume less fuel, translating into lower emissions and cost savings for drivers.

- Abrasiveness: Cenospheres enhance abrasion resistance in automotive materials, ensuring longevity and durability.

The Art of Coating: Lightweight, Insulating, and Durable.

The world of paint and coating experiences a revolution with the addition of Cenospheres:

- Weight Reduction: Cenospheres reduce the weight of paint and coating materials, facilitating application and extending their lifespan.

- Insulation Properties: These microspheres provide thermal insulation, enhancing energy efficiency and temperature control.

- Acoustic Insulation: Noise reduction properties contribute to a quieter environment, making spaces more pleasant.

- Abrasion Resistance: Cenospheres improve the resilience of paints and coatings, ensuring they withstand wear and tear.

Meeting High Temperatures Head-on with Insulation and Strength.

In refractories, Cenospheres play a vital role in enhancing materials used in high-temperature applications:

- Insulation Properties: Cenospheres enhance insulation capabilities, ensuring that refractory materials perform exceptionally well in extreme heat.

- Weight Reduction: By reducing the weight of refractory linings, installation and maintenance are made more manageable.

- Abrasiveness: Cenospheres improve abrasion resistance in refractories, guaranteeing long-term performance in harsh conditions.

Why Choose ORIENT?

- Uncompromising Quality: We deliver Cenospheres of the highest quality, meticulously processed to meet and exceed industry standards.

- Tailored Solutions: Our extensive range of Cenosphere sizes and grades enables us to customize our offerings to meet your specific requirements.

- Global Reach: With a global customer base, we have the experience to ensure timely deliveries worldwide and provide responsive customer support.

- Expertise: Our team boasts deep expertise and a wealth of knowledge in Cenospheres, allowing us to offer personalized solutions for your unique applications.

At ORINET, we are dedicated to helping you harness the full potential of Cenospheres for your industry. Contact us today to explore the countless possibilities this remarkable material offers.

Product datasheet

Specification | ULS-105 | ULS-300 | ULS-500 |

Physical Properties: | |||

Particle Size (Micron) | 5-105 | 5-300 | 5-500 |

Specific Gravity (g/cc) | 0.70 – 0.80 | 0.75 – 0.85 | 0.78 – 0.85 |

Bulk Density (g/cc) | 0.32-0.42 | 0.35-0.45 | 0.35-0.48 |

Appearance | Off-white Powder | Off-white Powder | Off-white Powder |

Sinkers (% by wt) | 3% max | 3% max | 3% max |

Moisture (% by wt) | 1-2% max | 1-2% max | 1-2% max |

pH | 7 to 8 | 7 to 8 | 7 to 8 |

Hardness Mohs Scale | 5 to 6 | 5 to 6 | 5 to 6 |

Crushing Strength (psi) | 3000-4500 | 3000-4500 | 3000-4500 |

Loss of Ignition (%) | 2% max | 2% max | 2% max |

Thermal Conductivity (w/mk) | 0.11 | 0.11 | 0.11 |

Oil Absorption (g oil/100 g) | 16-20 | 16-20 | 16-20 |

Approx. Softening Point (°C) | 1200-1250 | 1200-1250 | 1200-1250 |

Approx. Melting Point (°C) | 1400-1450 | 1400-1450 | 1400-1450 |

Chemical Compositions: | |||

SiO2 | 50 – 60 | 50 – 60 | 50 – 60 |

Al2O3 | 25 – 35 | 25 – 35 | 25 – 35 |

Fe2O3 | 1-3% | 1-3% | 1-3% |

Alkalis | 2% max | 2% max | 2% max |

Sieve Analysis: | |||

Size in Micron | % (Approx.) | ||

-500 | 0.1% max. | 98% | 98% |

150 | 98% | 17-22% | 17-22% |

75 | 44-48% | 44-48% | 44-48% |

-75 | 30-34% | 30-34% | 30-34% |

Packaging | |||

Standard | HDPE jumbo bags with 100%. dust-proof | HDPE jumbo bags with 100%. dust-proof | HDPE jumbo bags with 100%. dust-proof |

Custom | As per Buyer’s request | As per Buyer’s request | As per Buyer’s request |

Download TDS | Download TDS | Download TDS | |

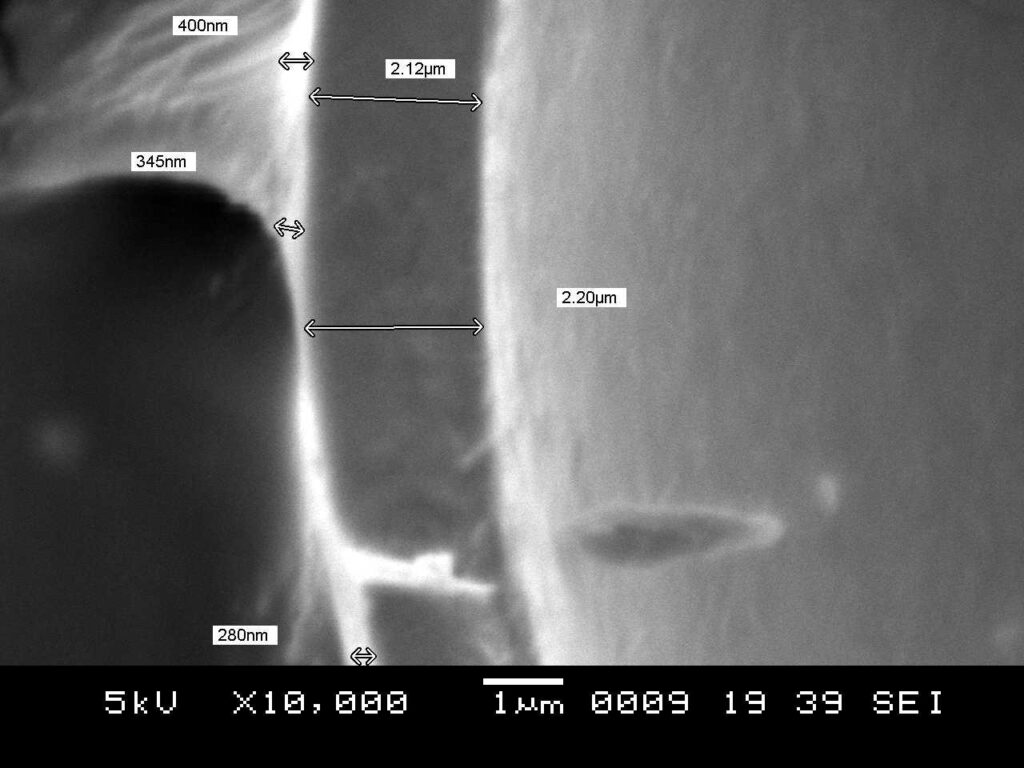

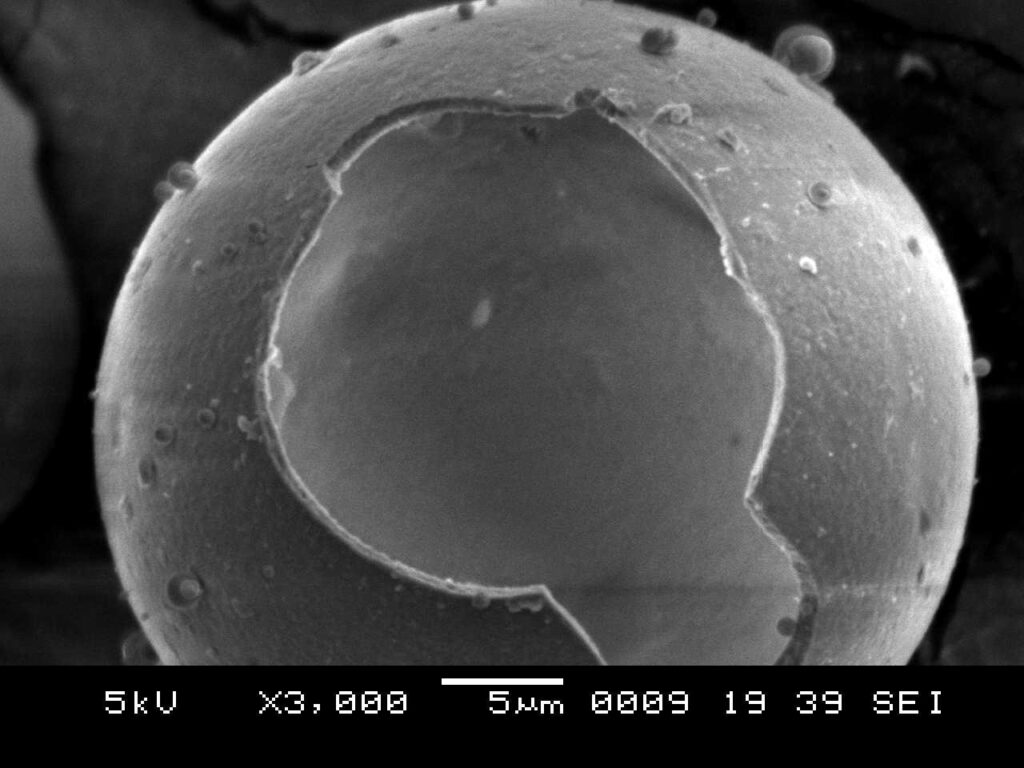

Microscopic photographs of ULS:

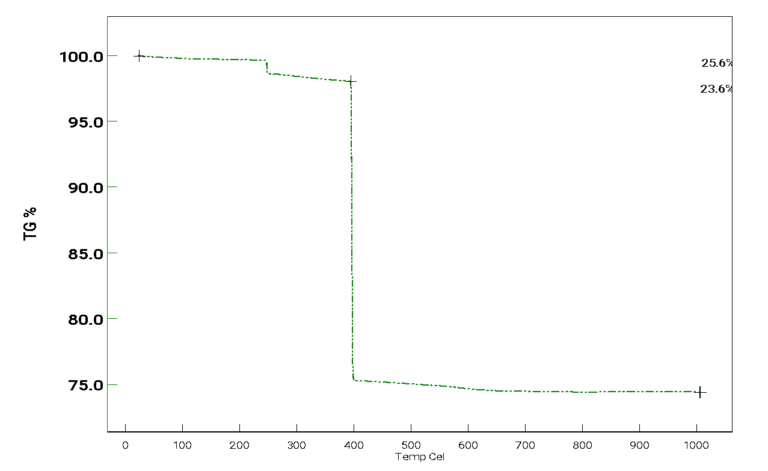

Thermogravimetric Analysis of ULS: